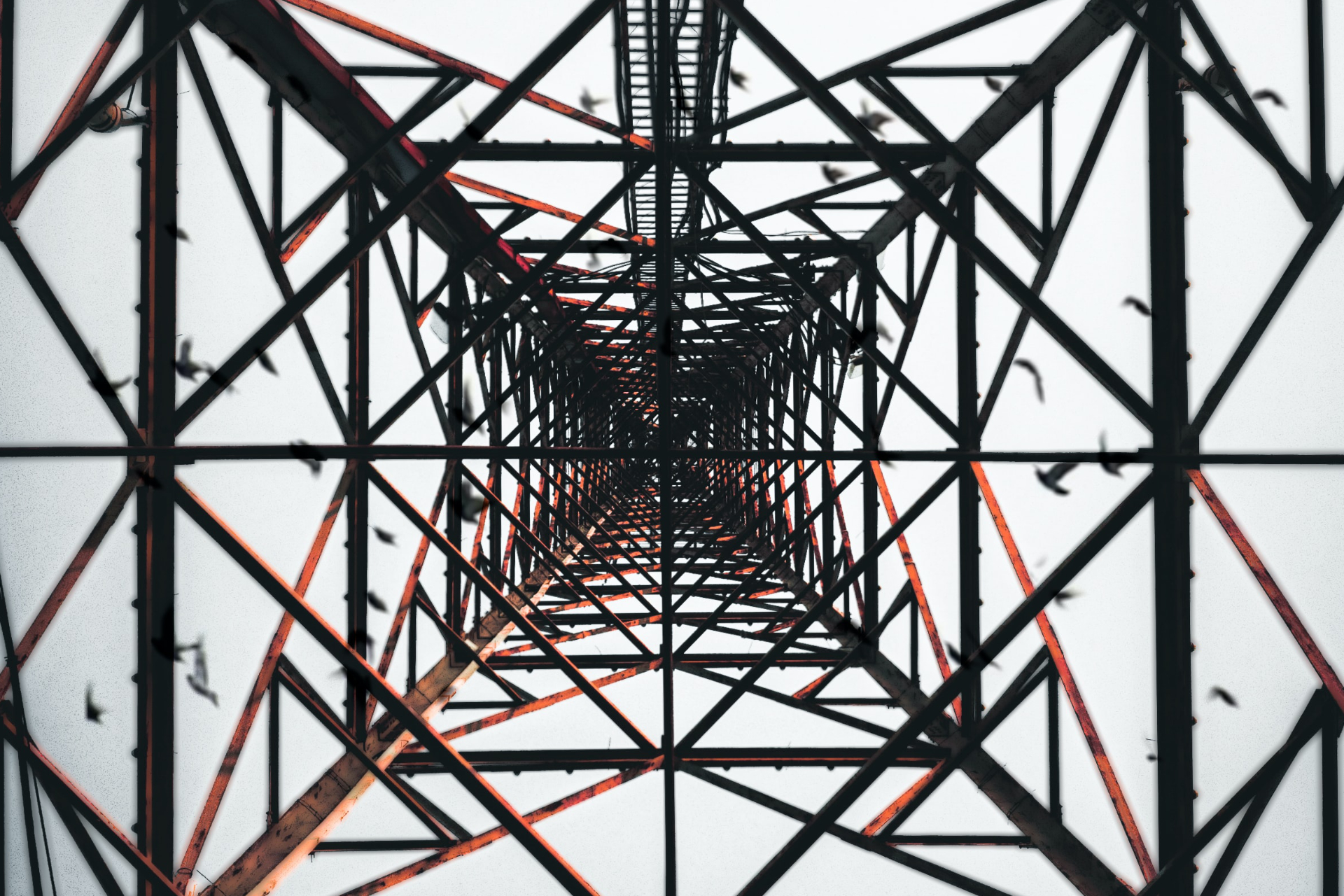

With our multidisciplinary experts, we can support our customers in all inspection requirements, at every stage of their facility’s life cycle, from construction, routine on-site inspection to decommissioning. Our teams, many of which are also trained in industrial rope access, enable us to access even remote locations.

Now, with the use of built-in IoT sensors in physical assets, continuous real-time data collection can be performed, which is then transmitted to a cloud platform for evaluation, analysis and forecasting. This way issues are identified ahead and are resolved, reducing operating costs. This becomes proof of the value of this service.